In the clean energy industry, the "coal gasification process" plays a crucial role in converting solid coal into gaseous fuel. This process involves subjecting coal to chemical reactions with gasifying agents in specific equipment, resulting in the production of combustible gases such as CO, hydrogen, methane, as well as non-combustible gases like carbon dioxide and nitrogen. These gases are then supplied to various industries and used in different production processes.

Case Background

This case focuses on a use enterprise operating in the clean energy industry, which supplies various gases to chemical companies in the region.Their production process involves coal combustion in a gasifier. The combustion process generates white ash, which needs to be collected and stored in a silo. Insufficiently burned coal forms black ash, which undergoes combustion again.

In the past, the level of white ash in the silo was measured using a plumb bob level gauge. However, this mechanical measuring method resulted in high maintenance costs and frequent issues of "buried plumb bob," impacting measurement accuracy and production.

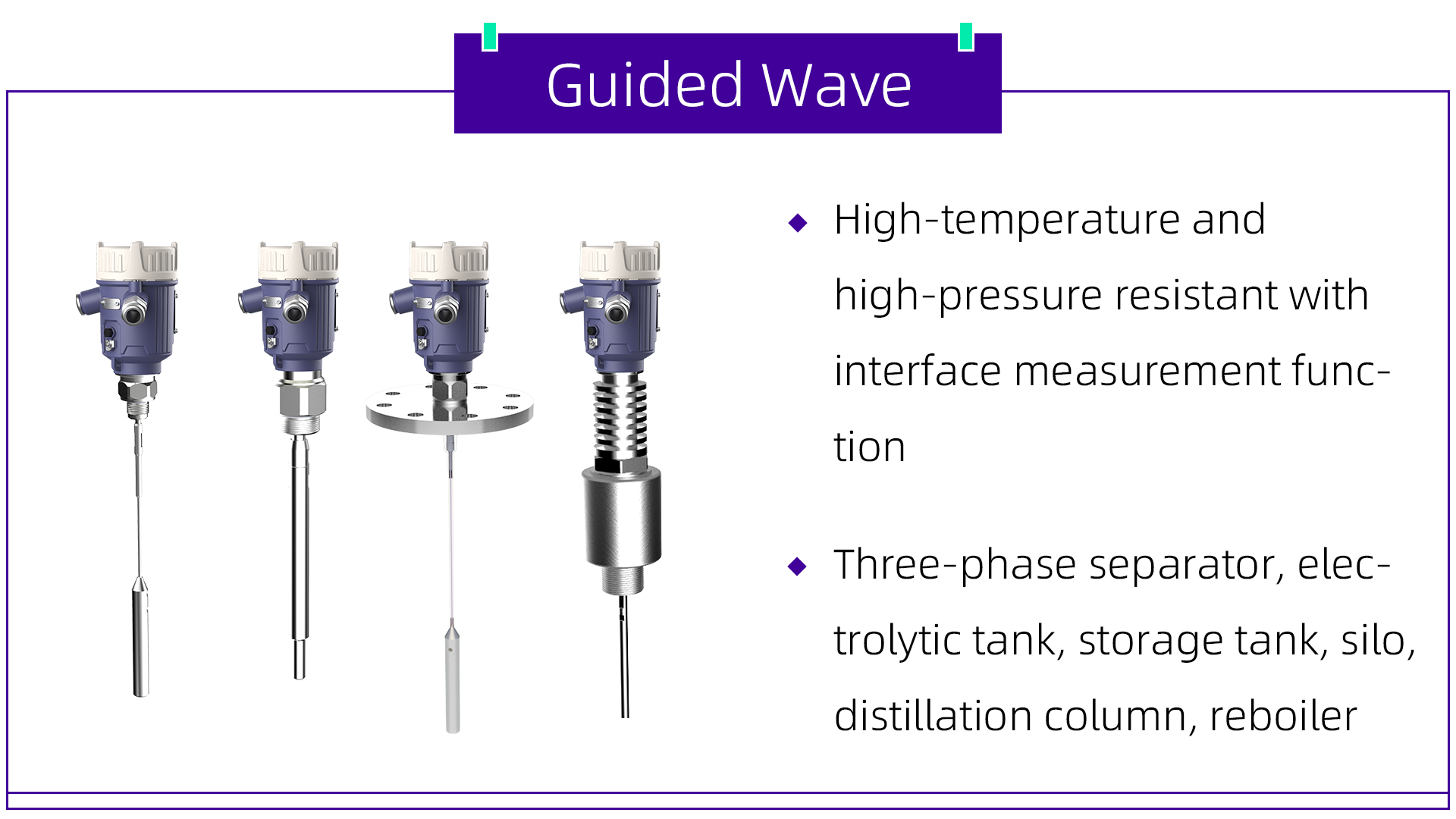

To address these challenges, RETTAR customized a guided wave radar level meter, ensuring accurate and stable measurement.

Measurement Challenges

1. The height of the silo, approximately 21.5 meters, required an instrument with high energy intensity.

2. The presence of a 1-meter high upper pipe in the silo posed installation challenges and increased the risk of interference, leading to inaccurate measurements.

3. The significant amount of dust generated during feeding caused interference signals, affecting the measurement accuracy.

Solution

To overcome these callenges, a contact-type guided wave radar level meter was selected for measurement. Considering the difficulty of installing rod antennas in applications with a large measuring range, a combination of "rigid rod + flexible cable" antenna form was customized for the customer.

This design ensured that the antenna did not touch the wall during the measurement process, eliminating the risk of "falling off the rod" and facilitating installation.

Product Advantages

1. The guided wave radar level meter is unaffected by material fluctuations and effectively combats signal interference caused by dust during feeding, resulting in more reliable signal reflection, avoiding wave loss, and ensuring accurate and reliable measurements.

2. Unlike the previously used plumb bob level meter, the guided wave radar level meter does not rely on mechanical movement for measurement. It has no moving parts, providing high reliability and a long service life, eliminating the risk of "buried plumb bob."

3. The instrument features a dual CPU design system and equivalent sampling pulse patent technology, offering strong hardware processing capability, high signal resolution, and sensitivity, ensuring optimal measurement performance.

4. The radar continuous measurement waiting algorithm for solid materials enhances measurement reliability.

With 17 years of experience in the research, development, and production of industrial level measurement instruments, RETTAR is dedicated to providing measurement products and solutions for various industries and applications.

Whether it's product development or complex on-site applications, our expertise and experience can meet your needs. Feel free to contact us for inquiries!