Maritime transport plays a vital role in China's socio-economic development, accounting for 80% of international cargo transportation. However, leaks in transport ships during loading and unloading of liquid cargo can result in economic losses and marine pollution.

To ensure the safety of ship operations and prevent fires or marine pollution caused by overflow due to high liquid levels, accurate monitoring of liquid levels in ship compartments is crucial.

Case Background

In this case, the ship specializes in the transportation of hazardous and flammable chemicals, some of which emit toxic and harmful gases. Exposure to rainwater can lead to chemical reactions, making the storage tanks unstable and releasing concentrated toxic gases into the air, posing significant risks.

The previously used radar level meter failed to accurately measure the liquid level in each storage tank due to poor sealing, corrosion resistance, and weak signal strength.

To address these challenges, Rettar conducted in-depth research and developed a customized radar level meter that achieved precise and reliable measurement, gaining high recognition from the customer.

Measurement Challenges

Ship instruments are susceptible to seawater erosion, and there is a strict prohibition on leakage for extremely dangerous media.

Therefore, the instrument requires high sealing and resistance to seawater corrosion. Ship compartments often have complex structures with high temperatures and heating coils, necessitating instruments that can withstand these conditions and shield against interference waves.

Additionally, the presence of a wide variety of goods in chemical transport ships introduces uncertainty regarding low dielectric constant media, requiring a solution to address bottom reflection waves

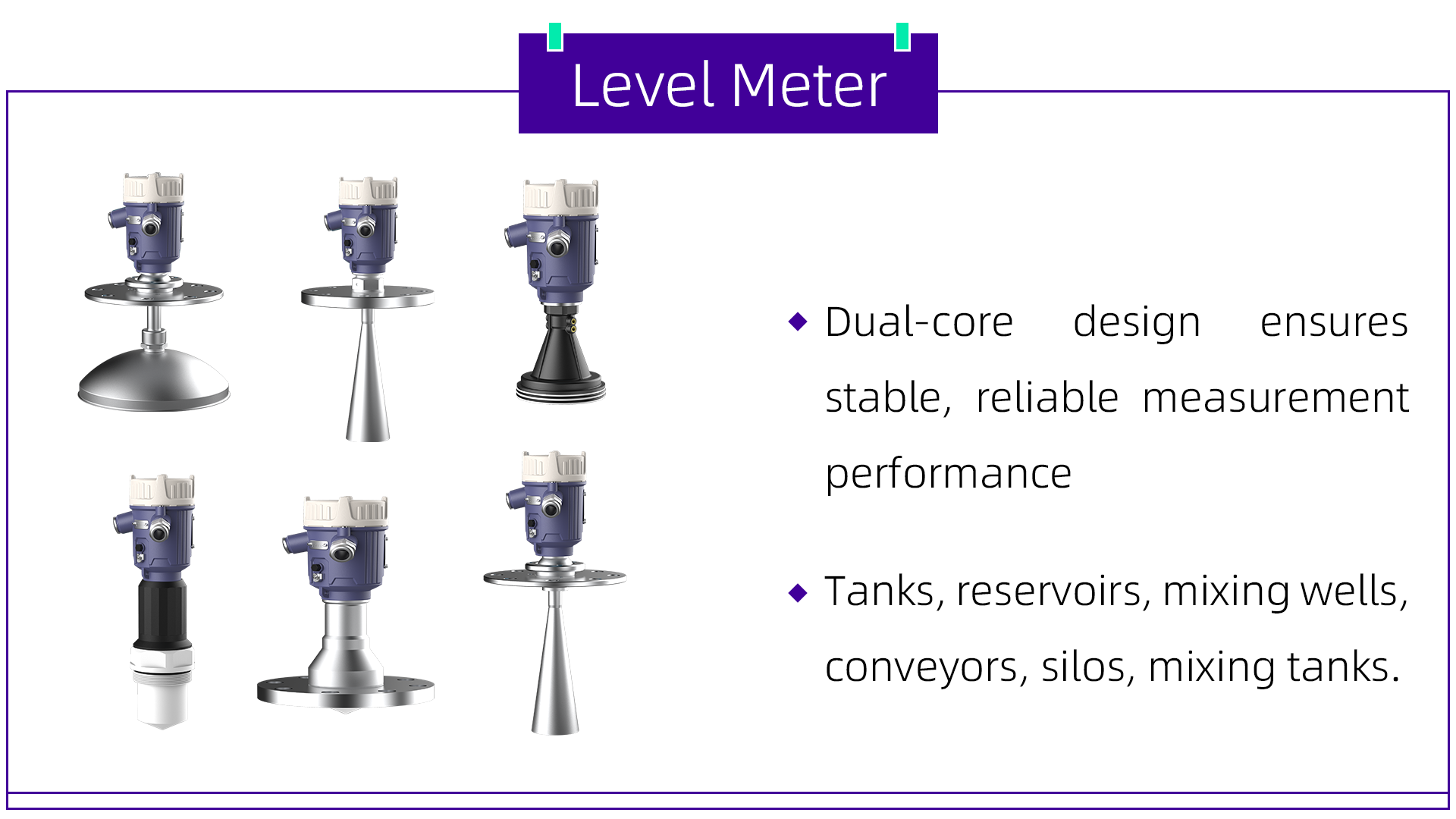

Instrument Selection: CPR6300 Liquid Corrosion Cone Type Radar Level Meter

Product Advantages

The CPR6300 radar level meter offers several advantages for measuring liquid levels in ship compartments and storage tanks:

Integrated PTFE-sealed antenna and stainless steel housing provide corrosion resistance and prevent leakage of stored chemicals, ensuring marine pollution prevention.

Powerful software algorithms effectively filter out interference waves generated by the complex structure inside ship compartments, ensuring accurate measurement.

The instrument can withstand high temperatures and has a strong signal focusing ability, enabling accurate measurement even for media with low dielectric constants.

On-Site Case

The CPR6300 series radar level meter has been successfully deployed in measuring liquid levels in ship compartments and storage tanks. Its robust anti-interference capability, meticulous design, and high-quality materials enable it to handle complex applications with stringent performance requirements.

RETTAR has been a leader in the research, development, and production of industrial level measurement instruments and related products for 17 years.

With extensive experience in product development and complex on-site applications, RETTAR provideshigh-quality measurement products and solutions for a wide range of industries.

Contact us to learn more about our offerings!