Ships and Marine Engineering

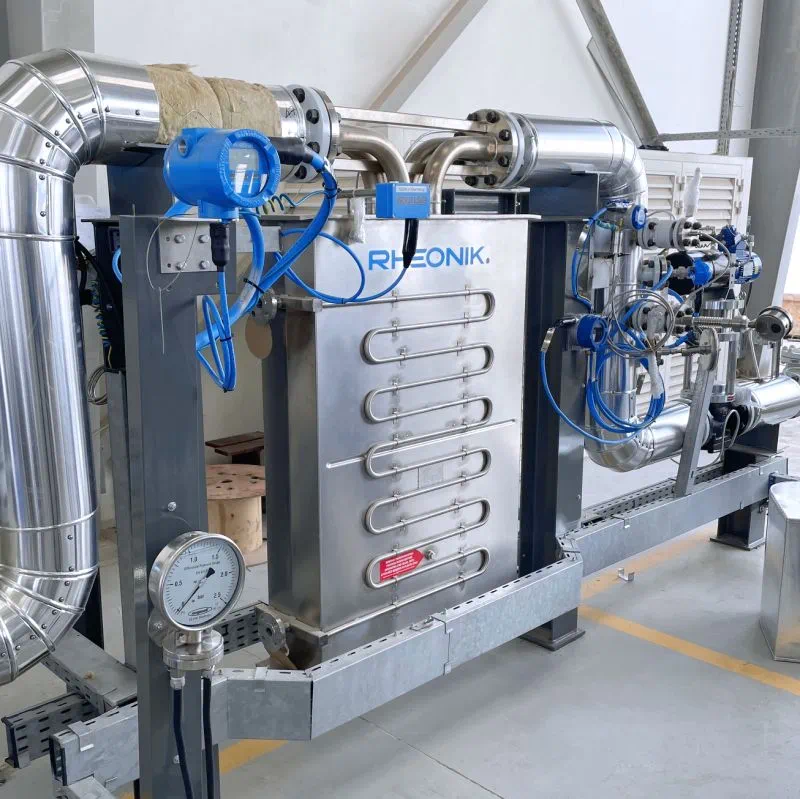

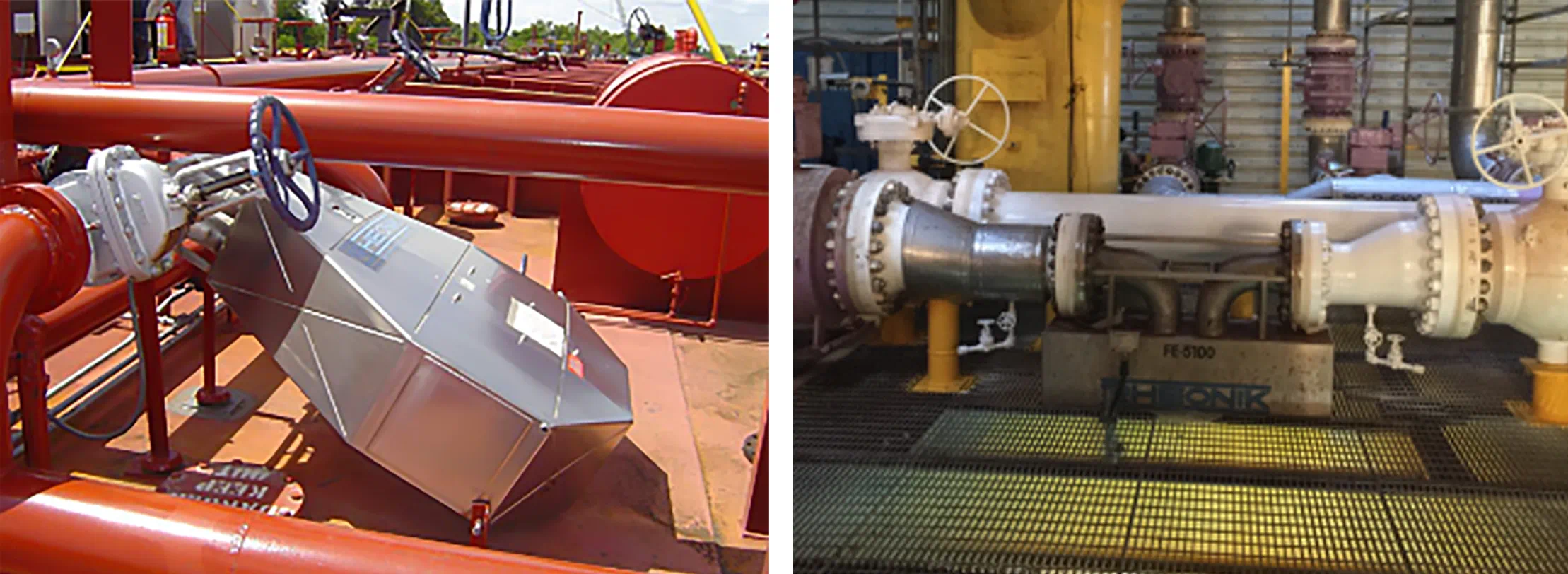

In the field of ships and marine engineering, due to its sturdy structure and resistance to high temperature and pressure, it can withstand sudden harsh environments at sea. Combined with its advantages such as high-precision measurement, it can be applied in fuel oil transportation and metering, offshore platforms and oilfield centralized production and transportation, wellhead transportation measurement, leakage monitoring, etc.

If you are interested in 3D laser scanner or become our distributor, you can contact us through the Email. We look forward to hearing with you!