RETTAR as a well-known provider of visual solutions for digital factories in the industry, has always pursued technological innovation and is committed to integrating cutting-edge technology into every aspect of industrial production, assisting in achieving intelligence and efficiency in industrial production.

Recently, we have launched two laser products -3D laser scanner and belt laser flowmeter, which will accurately serve the cutting-edge fields of "intelligent feeding" and "intelligent conveying". We provide more comprehensive and efficient solutions to achieve higher efficiency and more precise control in the production process.

Let’s explore more about these two new products.

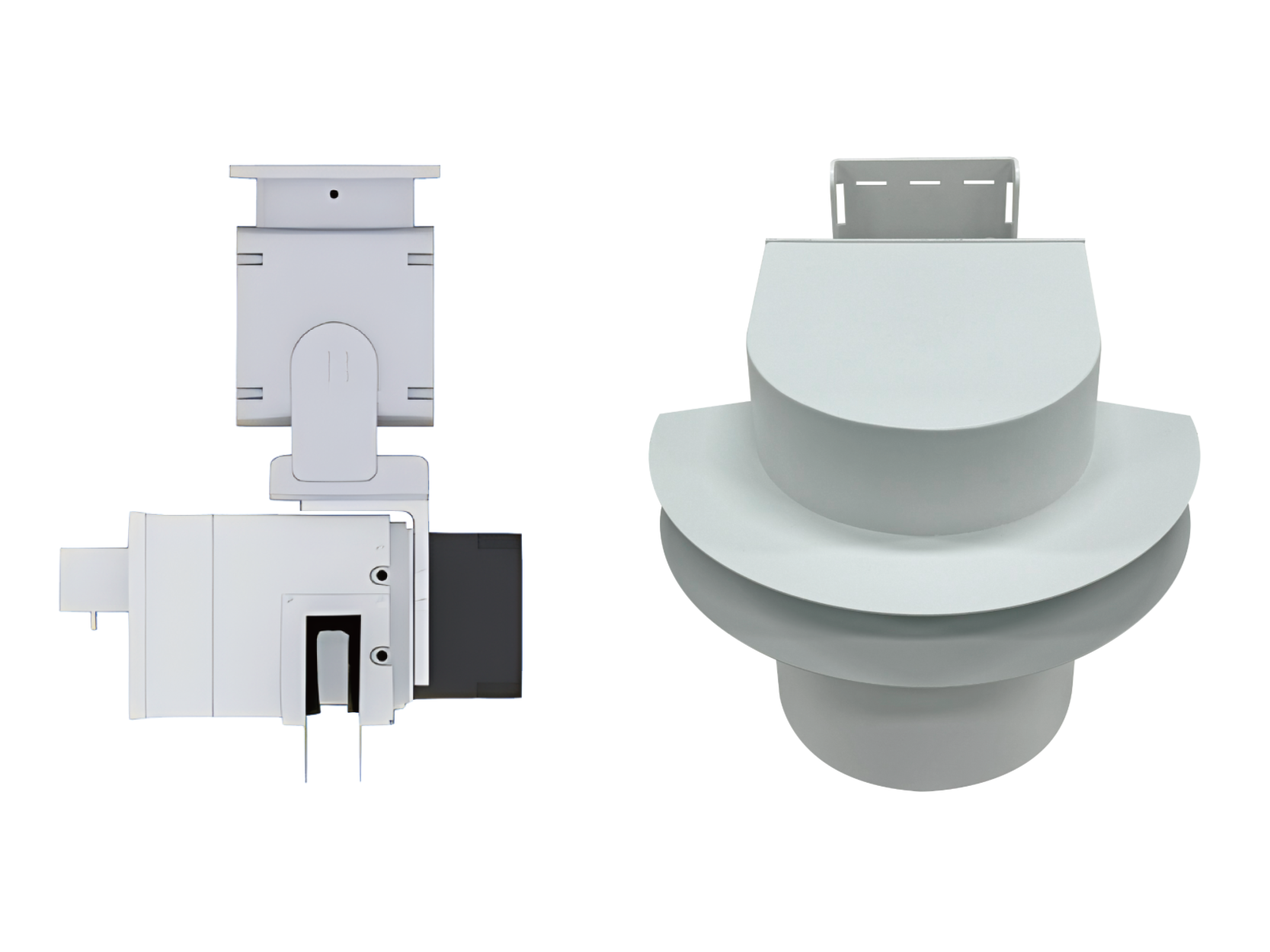

3DPro250X Series 3D Laser Scanner

The 3DPro250X series laser scanner uses laser ranging technology to perform 3D scanning and measurement of material heaps, and combines intelligent algorithms and other technologies to analyze and process 3D point cloud data, including key information such as material level coordinates, volume, and mass. At the same time, it can also work in collaboration with the bucket wheel crane cantilever or overhead crane, relying on its path of motion to scan the material pile in real time and improve material management efficiency.

Product Advantages

3D perspective: The shape of the material is clearly visible.

Intelligent data: Point cloud technology guides the progress of automated processes.

Real-time inventory: Real time monitoring ensures the accuracy of cost calculations.

Security protection: The over limit reminder function ensures the safety of storage and prevents potential risks.

Historical records: The data query function allows the export of required information for in-depth analysis at any time.

Area management: The layering of material areas ensures orderly and efficient management.

Intelligent control inventory: Planned management enables manual control anytime and anywhere.

Seamless Integration: Customized system with strong compatibility and simple operation.

Case Study

Cement platform inventory

Background:

Inventory material: quartz sand.

Yard area: 21000 square meter.

Requirements:

The cement plant will adopt the installation of 3D laser scanners to replace manual material inventory, achieving automated inventory of materials, 3D point cloud display of the yard, and material warning in the material area.

Solution:

According to the project construction requirements, the system design uses a 3D laser scanner to scan the material yard in real-time. Combined with the travel of the overhead crane, the data is processed through a radar application unit to achieve functions such as 3D point cloud display of the yard, automatic inventory material area, area management and warning in the material area.

Power plant inventory Management

Background:

Inventory material: raw coal.

Yard area: 47000 square meter.

Requirements:

A newly built coal shed in power plant to meet the needs of automated material inventory and unmanned operations, and in order to achieve the goals of digital construction and increase efficiency by reducing labor costs. Customer has been decided to build an automated material inventory system. By installing a laser detector on the bucket wheel loader, automated inventory of materials in each material area of the coal yard, 3D point cloud display of the yard, material warning, and reliable data are provided for unmanned operation of the bucket wheel loader.

Solution:

According to the requirements, the system design uses a laser scanner to scan the material yard in real-time. Combined with the travel of the overhead crane, the data is processed through a radar application unit to achieve functions such as 3D display of the material yard, automatic inventory material area, area management and warning in the material area.

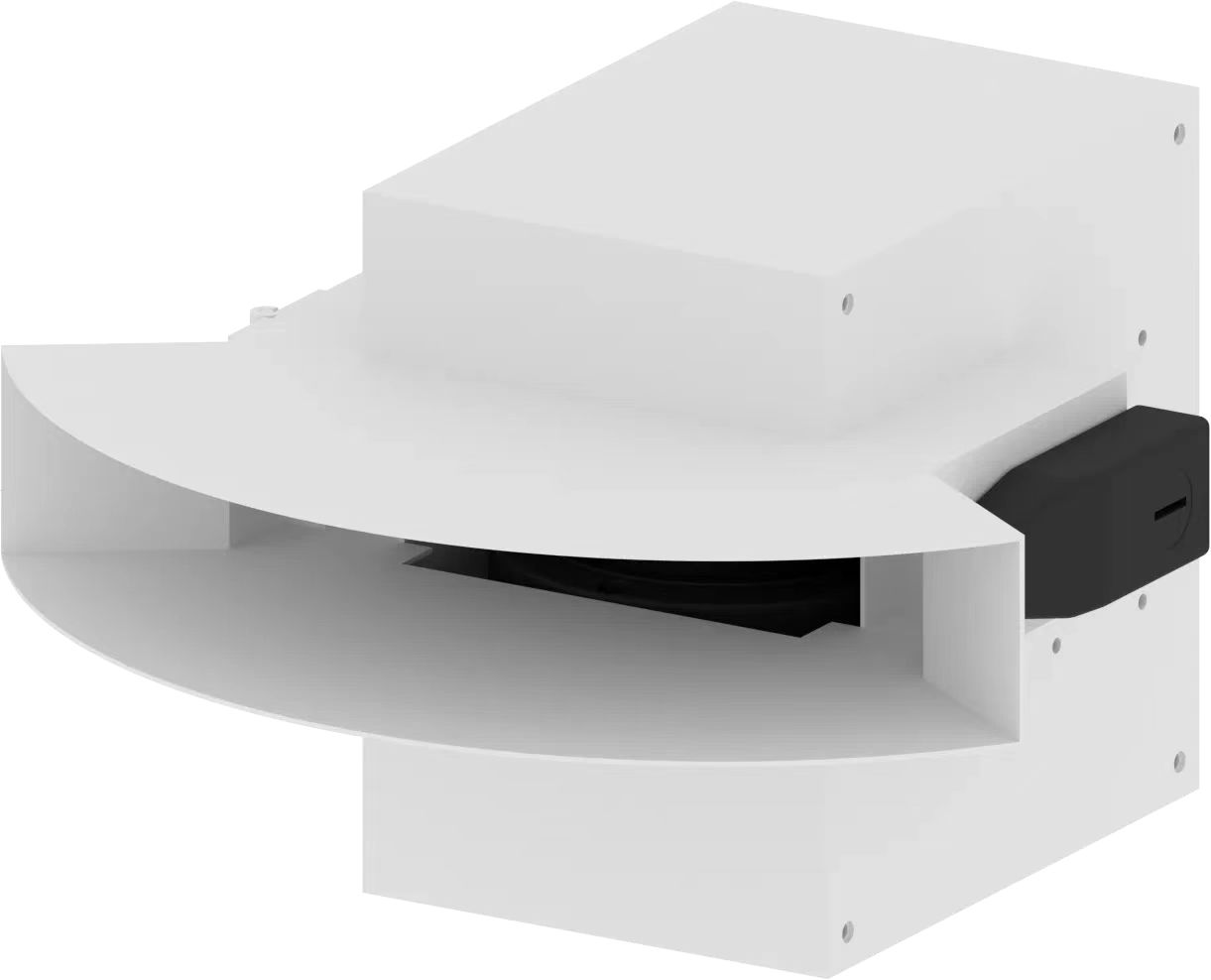

2DBL2901 Belt Laser Flowmeter

The 2DBL2901 belt laser flowmeter scans the surface of material by using laser rays, and combines the operating speed of the conveyor belt with intelligent algorithms to achieve real-time monitoring of the transportation flow of the conveyor belt.

Product Advantages

Laser scan:Accurate laser measurement makes material flow rate clear.

3D imaging:Real time 3D imaging makes material distribution more visible and clearer.

Real-time data:Point cloud data output makes process automation easier.

Dual monitoring:Dual monitoring of volume and flow rate makes material management more efficient.

Intelligent alarming:Timely response to traffic warnings ensures safe production.

Stable monitoring:Real time monitoring of belt status ensures stable and reliable operation.

Historical records:Historical data makes production analysis more convenient.

Case Study

Port belt flow monitoring

Background:

Inventory material: raw coal.

Number of belts: 4

Requirements:

A port belt conveyor does not have flow statistics and status detection functions, and with the large-scale transportation system and the remoteization of transportation belts, manual flow statistics and maintenance cannot guarantee the accuracy of statistics, and the cost of operation and maintenance is too high. Based on the consideration of conveying flow and abnormal situations during transportation, a reliable, stable, and accurate detection plan is needed on site.

Solution:

According to the project construction requirements, the system design uses a laser detector to scan the transportation belt in real-time, achieving real-time monitoring of belt transportation flow and cumulative flow monitoring, belt deviation detection, alarm, and transfer station blockage warning functions.

If you are interested in 3D laser scanner or become our distributor, you can contact us through the Email. We look forward to hearing with you!